By John Schroyer

Growing marijuana on a commercial scale isn’t cheap.

Startup costs for cultivation sites can run well over $1 million in heavily regulated states, while monthly expenses can easily stretch into six figures, according to data from the 2015 Marijuana Business Factbook.

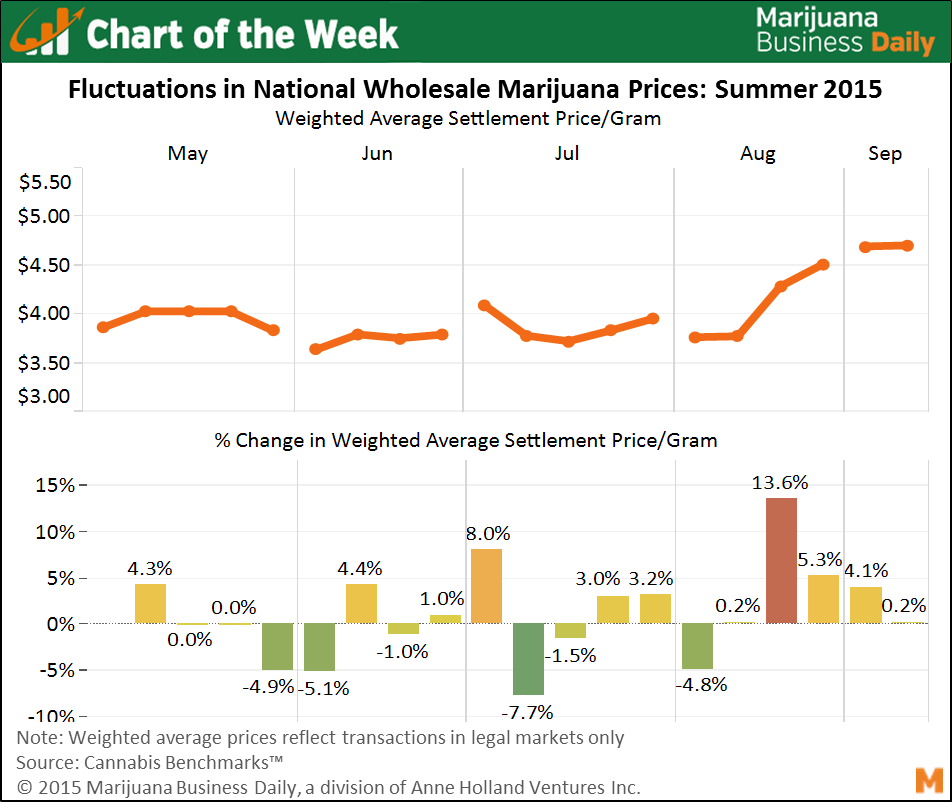

With wholesale markets in competitive states such as California, Colorado and Washington driving prices downward, controlling costs at professional grows is a must for cannabis cultivators that want to remain competitive.

To that end, Marijuana Business Daily consulted some industry experts to see what steps they rely on to control costs at their grows. Here’s what they suggested.

Invest at the Outset

While most businesses in any industry try to keep startup costs as low as possible, that isn’t necessarily the best way to proceed when opening a grow.

Creating a cost-efficient cultivation site often involves investing in technology and processes that may result in a big near-term hit, said Matt Sampson, owner of Washington State’s North Coast Growers.

Optimally, he said, growers need to be able to produce quality cannabis for $1 a gram.

“When we were planning and building out our first facility, we continued to make decisions along the way to make our facility more efficient to operate, even though in the end it resulted in our start-up costs tripling from our initial projections,” Sampson said.

That means spending money on technology that will reduce costs in the long run. For example, North Coast Growers put $30,000 into a state-of-the-art water system, which saves the company seven man hours a day. The firm also invested in a high-tech irrigation system.

Automate When Possible

Although machines won’t fully replace humans anytime soon when it comes to growing cannabis, they can certainly help lower costs. Automated trimmers can both speed up the process and cut down on unnecessary labor expenses, said Tim Cullen, the CEO of the Colorado Harvest Company.

That’s one of the reasons he uses a Twister automated trimmer in his 55,000-square-foot cultivation facility.

“We still have some trimmers, but we used to have an army of them, and now we just have a couple of people who do it. That’s one place we were able to gain some efficiency,” Cullen said.

Luke Ramirez, a co-owner of Denver’s Walking Raven cannabis shop, also purchased a similar trimmer in early August for his grow. He estimates it’ll save his company 35% on payroll costs.

Cullen also paid for an Agrotech environmental monitor that keeps track of the temperature, adds nutrients to plants and tracks pH and acidity levels.

“There’s a lot of savings in automate some of that, but that being said, the production of cannabis is a very hands-on, people-oriented physical sort of a job,” Cullen said. “We’re never going to replace eyeballs on plants and people being in the production facility.”

Watch the Meter

As just about any professional cultivator will tell an outsider, energy consumption is often a grower’s biggest cost and concern.

In Oakland, for example, Dark Heart Nursery’s utility bill includes a provision that charges the company a sizable chunk more if it uses power at a certain time of day.

“If I accidentally leave my lights on for five minutes too long, that could be a two or three thousand dollar charge,” said Dan Grace, Dark Heart’s owner and president. “So making sure your clocks are synchronized with the utility company can be a very valuable effort.”

Considering where to set up a grow based on utility rates can also be a big factor, said Sampson, in particular because energy bills are around 12-15% of his company’s total operating costs.

“In the county we chose, Skagit County, our power rates are 5.5 cents per kilowatt hour, whereas the rates for the county next to us, San Juan County, are over 11 cents a kilowatt hour. In some places in Washington State, rates are over 15 cents. That’s huge,” Sampson said.

Maximize Labor Efficiencies

Aside from adopting technology that helps reduce payroll costs, cannabis cultivators can take numerous steps to bolster employee productivity.

“It’s really about labor,” Grace said.

Ramirez added that investing in a cultivation workforce can also pay dividends and save money over time.

“I’d recommend putting growers on some type of salary, as well as bonuses, so they get paid if they produce a certain amount of product and if that product has a certain level of quality as well,” Ramirez said. “You can really gobble up a lot of dollars on the staffing side if you don’t have that dialed in.”

Pay Attention to Details and Be Creative

“There are a million different things” you can do to cut costs – you just have to get creative, Ramirez said.

One of the best pieces of advice he has is to simply keep one’s eyes and ears open for cost-saving possibilities. For example, Ramirez partners with other companies to order supplies – such as nutrients – in bulk.

“Team up with a different grower or company that’s using the same product, and have one big mass order,” Ramirez suggested.

Cullen estimated he saves tens of thousands of dollars a year by avoiding brand-name nutrients, opting instead for cheaper brands that are just as good.

“There are brand names that are really expensive, but the plant doesn’t care…. if it came from a cheaper source,” Cullen said.

Dark Heart’s Grace added that even small things, such as paying attention to the condition of light bulbs, can turn into major money savers.

“One thing I’ve seen over and over again in grow rooms is bad lighting,” Grace said. “People are not checking their lighting levels, they’re not replacing their bulbs on suitable schedules, or sometimes, they have lenses, and they’re just not cleaning the lenses frequently enough. To me, that’s one of the biggest no-brainers.”

John Schroyer can be reached at johns@mjbizmedia.com