A lack of standards is among the factors plaguing the cannabis testing industry, threatening to undermine consumer confidence in marijuana products and making it harder for some testing businesses to operate, according to industry insiders.

But the problems don’t stop there, testing lab officials and regulators contend.

Some marijuana businesses – such as growers, processors and manufacturers – are shopping around for labs that will give them the results they want to see in the way of THC potency and contaminants, according to industry officials.

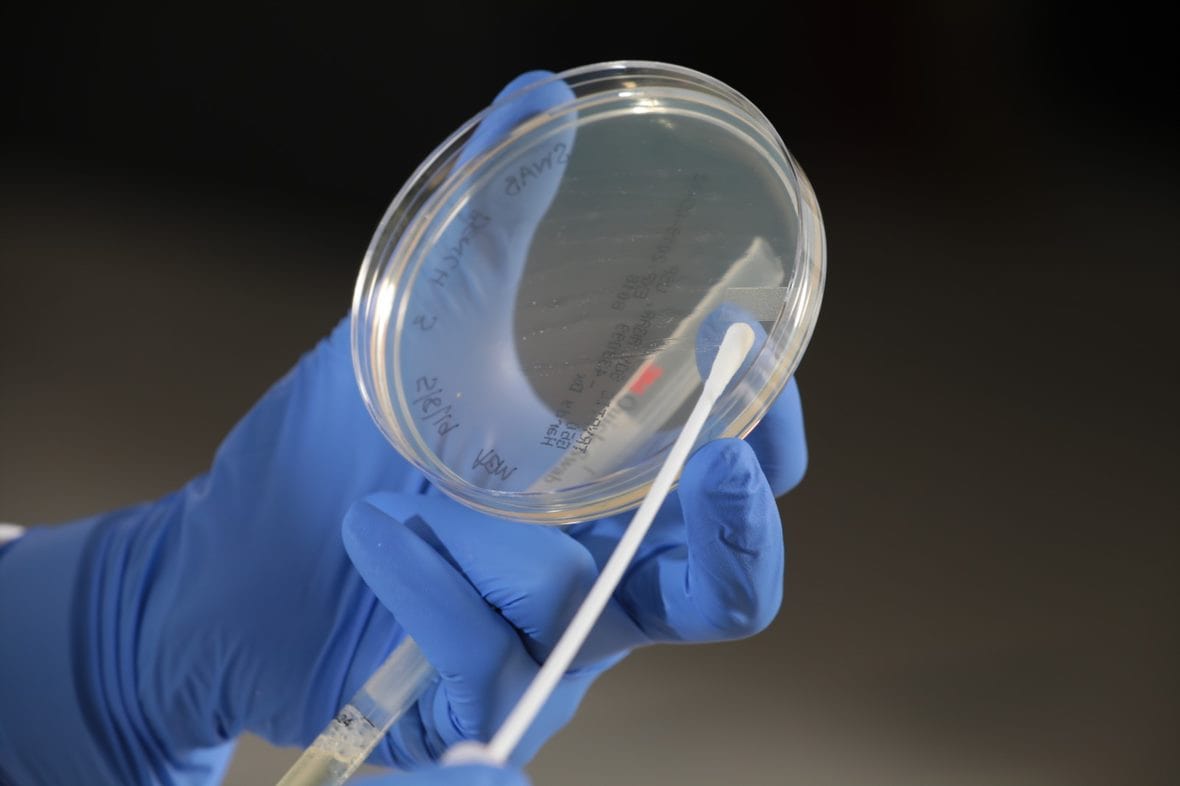

Other cannabis businesses are said to be sending in samples of their marijuana that have been adulterated with spray-on cannabis oil or dusted with THC crystals to give the impression of a higher THC content, among other practices.

Regulators, meanwhile, are shuttering testing labs for allegedly reporting results that don’t match up with audits.

Earlier this month, the Washington State Liquor and Cannabis Board (LCB) suspended the license of Praxis Laboratory for allegedly falsifying testing data on more than 1,200 samples of cannabis by providing higher THC numbers than tests actually found.

As it stands now, the Centralia, Washington-based lab is suspended for 180 days effective Dec. 10. While the lab is shuttered, state regulators will seek to permanently revoke its license.

According to an LCB release, “during the investigation the lab owner attempted to destroy evidence of falsified data in an effort to obstruct (the agency’s) ability to conduct a complete investigation.”

Praxis said in a statement to Marijuana Business Daily that the LCB’s decision was “in error and based on inaccurate information.” The lab is appealing the ruling.

In a separate statement to the Washington state cannabis community that was shared on social media, the company said, “This is a clear cut case of agency overreach and libel and we will be pursuing legal action immediately.”

The statement also noted that a disgruntled former employee stole data from the lab, then contacted the regulators.

Regulators elsewhere have shuttered cannabis labs for inaccurate or misleading test results.

In September 2019, the Nevada Tax Commission launched an investigation into marijuana testing labs in the state.

In February 2020, state regulators suspended the license of Certified Ag Labs and fined the business $70,000 for what was described as “inaccurate and misleading” potency in cannabis products that boosted THC levels by as much as 10%.

The lab was allowed to reopen.

A Certified Ag representative told MJBizDaily the company “had some bumps, but our data was plus or minus 10% and we stand behind it.”

Lab shopping

The practice of lab shopping – where cannabis growers or product makers look for a facility that will provide favorable results – has almost put Keystone State Testing out of business, said Dr. Kelly Greenland, CEO of the Harrisburg, Pennsylvania-based marijuana testing lab.

“We have clients who test with us and never come back because their numbers are higher elsewhere,” she said.

In addition to higher potency levels, some cannabis businesses also seek favorable results for contaminants, including microbials and heavy metals.

“There are a few labs out there saying, ‘Tell me what you want it to say, and I’ll put it on the label,'” Greenland said.

Pennsylvania’s regulations are adequate, she said, but they’re not being enforced.

“If you want to make sure this market is safe, you need to have safe regulations and you need to have your enforcement enforce the regulations that you’ve made,” Greenland said.

Testing labs promising quick turnaround times – less than 48 hours, for example – might be cutting corners. Greenland said it’s normal for a lab to take up to 72 hours to return results.

Growers and processors don’t have to try that hard to find good testing labs, according to Greenland.

But she added that often it doesn’t make good business sense to play by the rules, “as messed up as this sounds.”

A number of factors at play

The variability in testing results reflects a combination of factors, according to Alena Rodriguez, managing director of Rm3 Labs in Boulder, Colorado.

They include:

- Labs using different testing methods.

- Differing behavior among the businesses submitting samples for testing.

Rodriguez noted that variability exists among testing labs even in long-established industries with well-defined standards partly because labs operate with their own proprietary methods.

It’s not just standardization of methods that’s needed, she added, but also standardization of terminology.

For example, THC results can be defined on a dry-weight basis, but different cultivators have different drying and curing processes, and that can alter the results.

Not having homogenous samples is a core part of the problem.

Rodriguez said her lab often sees adulterated samples.

For example: Flower will come in sprayed with a sheen of distillate to increase the potency numbers. Or the flower might be “kiefed,” meaning dusted with additional THC crystals for the same reason.

In new rules scheduled for release on Jan. 1, 2021, the Colorado Marijuana Enforcement Division plans to classify adulterated test samples as a Class 2 misdemeanor.

Rodriguez said her lab can have the best scientists and spend huge sums of money on lab equipment. But it won’t matter if the samples do not truly represent the plants and products that are supposed to be undergoing testing.

Changes might be coming in the months and years ahead, however.

Rodriguez co-chairs the Marijuana Science and Policy Work Group, which is working on protocols for each business to train the employees who are submitting samples for testing.

Overall, Rodriguez said it just takes time for a new industry to develop the necessary standards.

“Give it another five to 15 years,” she said.

More collaboration needed

At hemp testing lab Sante Laboratories, in Austin, Texas, President Mike Sandoval said a lack of standards and enforcement of those standards across the country is a key problem for both the marijuana and hemp industries.

“Falsifying lab data should be a crime, at least at the state level,” he said.

In Texas, according to Sandoval, regulators don’t have the analytical background to properly understand the requirements a lab should possess to produce quality results.

Just because a lab is ISO-17025 accredited doesn’t mean it’s doing a good job, he added.

A key obstacle to improving testing quality is a culture of secrecy among the testing labs. According to Sandoval, “it’s impossible to get another lab on the phone” to discuss testing methods, including how samples are prepared.

He’d like to see an open platform where lab workers could discuss science and breakthroughs.

As in other states, Sandoval said producers often want results quickly that favor the goals of the business. Shortcuts can cause incorrect results, but when companies don’t get the results they want, they’ll seek out another lab.

And it’s not as if Sandoval wants to tell a company its sample is contaminated or has low-potency.

“The worst part of my job is delivering bad data,” he said.

Bart Schaneman can be reached at barts@mjbizdaily.com